Research

Miniaturized High-performance Filter Capacitor Based on Structurally Integrated Carbon Tube Grids

| By

A research team led by Prof. MENG Guowen from the Institute Solid State Physics, Hefei Institutes of Physical Science (HFIPS) of Chinese Academy of Sciences (CAS), cooperating with Prof. WEI Bingqing of the University of Delaware, Newark, USA, successfully developed a structurally integrated, highly-oriented carbon tube (CT) grids as electrodes of electric double-layer capacitors (EDLCs), to significantly improve the frequency response performance and the areal and volumetric capacitances at the corresponding frequency. It is expected to be used as a high-performance small-sized alternating current (AC) line-filtering capacitor in electronic circuits, providing the essential materials and technology for the miniaturization and portability of electronic products.

The results were published in Science on August 26, 2022.

Converting AC into direct current (DC) is vital for powering electronics. In the process, filter capacitors play a pivotal role in smoothing the voltage ripple in the rectified DC signal, ensuring the quality and reliability of electrical and electronic equipment. Aluminum electrolytic capacitors (AECs) are widely used in this field. Still, they are always the largest electronic component due to their low volumetric capacitances, which seriously restricts the development of miniaturized and portable electronic products.

EDLCs, usually with carbon materials as electrodes, are considered potential candidates for AC line-filtering to replace AECs due to their higher specific capacitance, in line with the trend of device miniaturization, but restricted by their low operating frequency (~1 Hz). Although the operating frequency can be enhanced by using highly-oriented carbon nanomaterials as electrodes, the specific capacitance is very limited. Meanwhile, the physical contacts between adjacent carbon nanotubes or graphene sheets would not only increase the resistance, further slowing the frequency response, but also make it difficult to increase the mass loadings of the carbon nanomaterials and thus obtain a large capacitance. There is an urgent need to develop newly-structured materials to increase the fast frequency response while maintaining high specific capacitance.

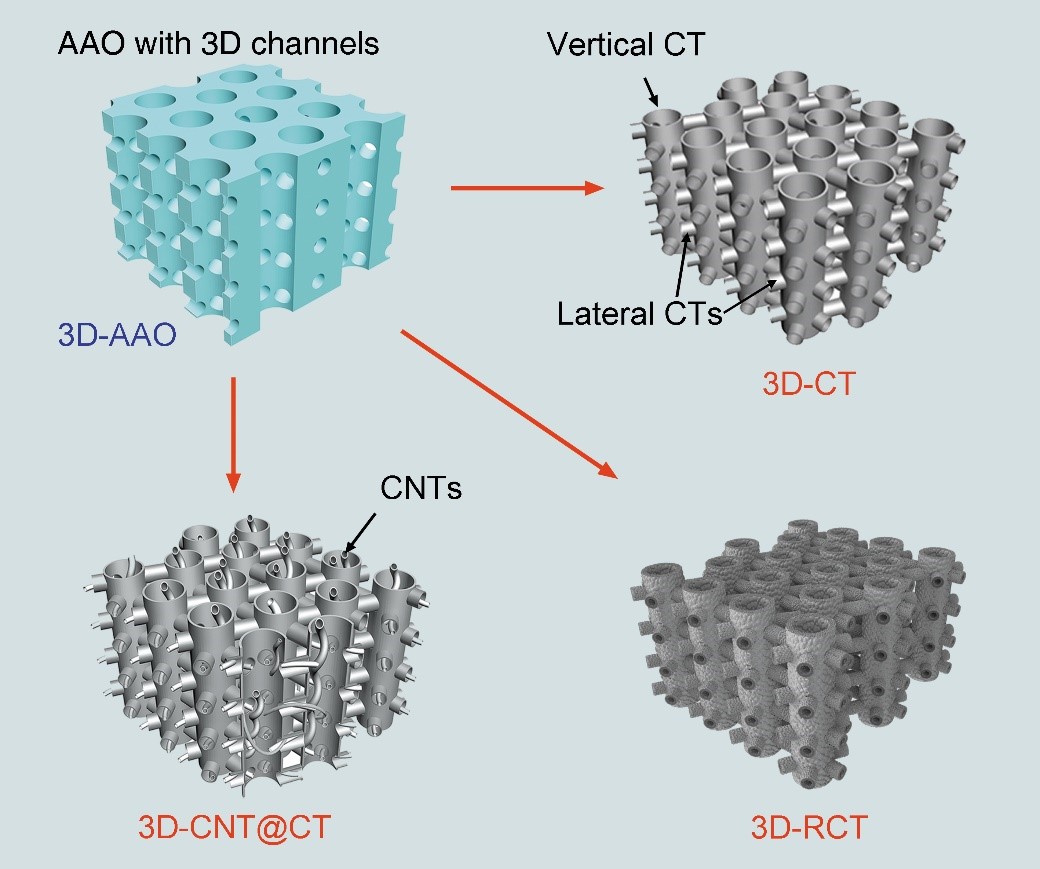

Since 2015, the research team has been working on this topic. After unremitting efforts, a new three-dimensional (3D) structure-integrated and highly-oriented CT array with laterally interconnected CTs by chemical bonds has been successfully developed. The 3D CT grid with truly-interconnected and structurally-integrated vertical and lateral CTs (denoted as 3D-CT) can provide highly oriented, high structural stability, superior electrical conductivity, and effective open porous structure (Figure 1), which is expected to meet the requirements of the electrode materials of the small-sized high-performance AC line-filtering EDLCs.

In order to obtain this unique structure, the researchers firstly anodized an aluminum sheet containing a small amount of Cu impurity, to obtain the highly ordered vertical porous anodic aluminum oxide (AAO) template containing Cu-impurity nanoparticles on the pore walls. Subsequently, a 3D interconnected porous AAO template (3D-AAO, upper-left corner in Figure 1) was obtained by selectively etching the Cu-containing nanoparticles on the pore walls with phosphoric acid.

The 3D-CT (upper-right corner in Figure 1) grid was synthesized by a chemical vapor deposition (CVD) method using the 3D-AAO template. To increase the specific surface area, and further enhance the specific areal and volumetric capacitance, the 3D-CTs can be modified, as exemplified by filling with much-smaller-diameter carbon nanotubes (CNTs) within the vertical and lateral CTs (denoted as 3D-CNT@CT, lower-left corner in Figure 1) via the Ni catalyst-assisted CVD method, or surface-treated with KMnO4 (3D-RCT, i.e., 3D-CT with a rough surface, lower-right corner in Figure 1).

The researchers directly used the 3D-CT grids as the electrodes to construct a series of symmetric EDLCs (Figure 2A). It was found that such capacitors have good frequency response performance (low resistance and a phase angle less than -80°, as shown in Figure 2B and 2C) and very high specific areal capacitance (2.81 mF cm-2 at 120 Hz, shown in Figure 2D).

More importantly, to reach high operating voltage, six 3D-CT grid-based EDLCs were connected in series, which also exhibited an excellent frequency-dependent performance (Figure 3A and 3B), and a promising filtering performance like a single EDLC (Figure 3C). It is largely due to the slight rise of the equivalent series resistance is compromised by a corresponding augmentation in capacitive reactance, ultimately leading to its fast frequency response. This proves that high voltage AC line-filtering capacitors can be achieved by means of connecting multiple EDLCs in series.

Furthermore, the 3D-CT grid-based EDLCs exhibit significant volumetric advantages over the comparably rated AECs in low-voltage operations (below 25 volts) (Figure 3D).

The findings provide a sound technological basis and key materials for developing EDLCs for miniaturizing AC line-filter and power devices, which would be helpful to replace the bulky AECs and realizes the miniaturization of portable electronics, mobile power supply, electrical appliances, and distributed energy harvesting and power supply on the Internet of Things, greatly promoting the development of high-performance digital circuits and emerging electronic technologies.

Funding was provided by Natural Science Foundation of (China grant: 91963202 and 52072372), Key Research Program of Frontier Sciences (CAS) grant QYZDJ-SSW-SLH046, CAS/SAFEA International Partnership Program for Creative Research Teams, and Hefei Institutes of Physical Science (CAS) Director’s Fund grant YZJJZX202018.

Figure 1. Schematic illustration of the synthesized 3D-CT grids: 3D-CT, 3D-CNT@CT, and 3D-RCT. (Image by HAN Fangming)

Figure 2. Assembly structure and electrochemical performances of the 3D-CT grid-based EDLCs. (A) Schematic of EDLC assembly structure. (B) Complex plane plot of the 3D-CT based EDLCs. (C) Phase angle versus frequency of 3D-CT-10, 3D-CNT@CT-10, 3D-RCT-10, 3D-RCT-12, and commercial AEC (Panasonic, Japan, 6.3 V/330 μF). (D) Comparison of the areal capacitance at 120 Hz of 3D-CT-10, 3D-CNT@C-10, 3D-RCT-10(12), and other reported EDLCs used in the AC filter circuits with the phase angle near or less than -80o. (Image by HAN Fangming)

- Attachments Download:

-

contact

Prof. MENG Guowen

E-mail: gwmeng@issp.ac.cn